- Home

- About

- Products

- Blogs

- Contact

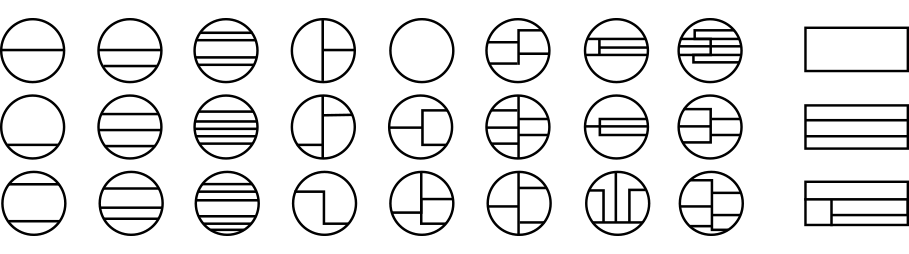

Heat exchanger gaskets come in several forms based on the type of heat exchanger or application. For simplicity’s sake, we use the terms metal jacketed, camprofile and plate to define the different types of heat exchanger gaskets, though there are numerous configurations for each type.

We precision engineer a wide range of gaskets for shell, tube, plate and frame heat exchangers gaskets, which are commonly used in operations involving steam generation and heating/cooling processes.

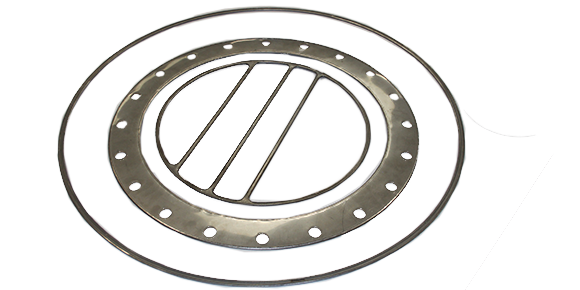

Heat exchanger gaskets and small spinner gaskets can be fabricated in simple rings or more complicated crossbar designs and configurations.

Composed of a grooved metal core and a graphite or composite sealing layer, camprofile gaskets are supplied in standard and nonstandard dimensions.

Rubber gaskets are essential components in plate heat exchangers. We precision manufacture gaskets to size and thickness to suit the PHE.

Metal jacketed heat exchanger gaskets can be supplied in circular or non-circular form, in standard or non-standard sizes. The gaskets are manufactured in different styles to API, ANSI, DIN and BS standards for all types of applications. The selection of gasket style and metal depends upon the operating conditions and the mechanical features of the flanged assembly.

We can also design custom metal jacketed gaskets based on customer specifications and our specialist knowledge ensures gaskets are fabricated to fit accurately and have an effective seal. Contact us to discuss custom requirements.

Our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications.

We supply a vast range of gasket materials, available to buy directly or order from us. For more information visit the Gasket Sheet Materials Document.