- Home

- About

- Products

- Blogs

- Contact

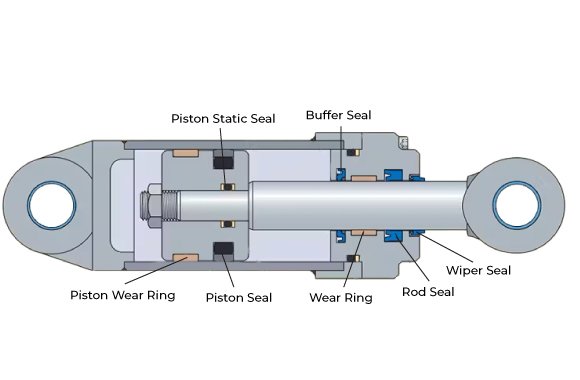

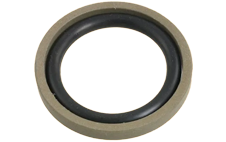

Pneumatic and hydraulic seals are designed to create a tight seal between the parts within a hydraulic cylinder. These cylinders consist of various components, some of which must endure high pressure, elevated temperatures, and exposure to fluids. Hydraulic seals are tailored to fit these specific components, ensuring a secure seal that prevents any fluid from escaping around them.

Hydraulic seals are either static or dynamic, depending on their application. Both seal types are used in hydraulic cylinders. The difference is that static seals remain stationary, whereas dynamic seals are exposed to motion. In general, there are four main types of Hydraulic seals.

Rod seals are one of the most critical seals in hydraulic equipment. They help prevent pressurised hydraulic fluid from leaking out of the cylinder whilst keeping contaminants out, extending the life of the cylinder.

Wiper seals wipe or scrape debris from the piston rod to prevent foreign particles from entering the sealing system. They are typically paired with rod seals to create a second layer of protection

Piston seals serve as a pressure barrier and prevent fluid from passing the piston, as the system pressure pushes the piston down the cylinder during a pressure cycle. They are designed for bidirectional pressures.

Wear rings, also known as Guide rings, keep the piston centralised. They are used to replace the more traditional bearings made from soft metal, as their low-friction properties mean they operate more effectively.

Several factors influence the choice of material, such as exposure to different media, pressure levels, temperature conditions, and potentially strict regulatory standards, especially in industries like food and beverage or oil and gas. Types of sealing materials include:

There are a range of criteria that must be considered before selecting the material for the seal. Fluid type, pressure, temperature and speed of operation all affect the choices made. Hydraulic seals have a crucial impact on system performance in many applications, and getting the material choice wrong can severely impact the overall performance and lifespan of the seal.

Dobsons Gaskets has a wealth of experience in manufacturing seals and will advise on and produce the right seal materials for your application. Get in touch today to discuss your gasket and seal needs.

Our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications.

We supply a vast range of gasket materials, available to buy directly or order from us. For more information visit the Gasket Sheet Materials Document.