- Home

- About

- Products

- Blogs

- Contact

As many countries pledge to become carbon neutral by 2050, hydrogen power heralds the future of renewable energy and is in increasingly high demand worldwide. Able to be converted into a wide range of resources including electricity and fuels, hydrogen can be stored for long periods, transported worldwide and used across a wide range of applications from energy production to oil refining and intensive industrial processes.

Hydrogen is a flammable, highly-reactive substance that places a lot of stress on the sealing materials in which it is contained. Selecting the correct material for your application is critical, with an efficient seal helping to minimise escaping gas and reduce the risk of prolonged exposure.

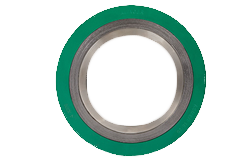

Our hydrogen-ready gaskets are durable, highly resistant to chemicals and fuels and have a low gas permeability, with our rigorous testing procedures ensuring that they are suitable for various processes involving 100% hydrogen and H2S, CO2 or natural gas. With over 50 years in the gasket manufacturing industry, our experienced team are on hand to provide expert advice on the correct materials for a wide range of sealing applications.

This composite material is suited to critical sealing against oils and chemicals, particularly where high temperatures may be present.

The cork and neoprene composite material provides excellent sealing and durability against heat and moisture in external conditions.

Natural cork has excellent compression, resilience and recovery properties and is a lightweight material that resists water and some oils.

Anti-vibration gasket material, such as Tico, is most commonly used to reduce machinery noise in many industrial processes.

EPDM gaskets are commonly used in highly abrasive processes involving acids, alkalines and other chemicals and conform to ICI M228 specifications.

Able to be reinforced with fillers including graphite and carbon, PTFE gaskets are highly hydrophobic and have a low coefficient of friction.

Due to their high chemical resistance and gas leak protection qualities, gland packings are a popular seal for corrosive environments.

Our plastic gaskets are well suited to hydrogen processes due to their minimal moisture absorption, durability and resistance to most chemicals.

Our H2 (Hydrogen Ready) gaskets are precision-manufactured to meet customer requirements in a wide range of sheet, wound and filler configurations to withstand high temperatures, pressures and chemicals. Utilising a range of laser, water jet, punch press and CAM machinery, we apply the same high level of detail whether producing large runs or one-off gaskets. All of our gaskets are rigorously tested and manufactured in accordance with national and international standards.

Due to the volatile nature of hydrogen, it is crucial to select the correct gasket material for your application. With excellent sealing properties and high resistance to temperatures, pressures and chemicals, our Hydrogen-Ready gaskets can be used in a wide range of formats and processes, from power generation to chemical processing and manufacturing.

Our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications.

We supply a vast range of gasket materials, available to buy directly or order from us. For more information visit the Gasket Sheet Materials Document.